Evaluation of Garment Simulations within an Analytical Fit Test

Let customers know they can rely on consistent fit - across your collection.

Sports bras offer different levels of support depending on their design and use. Verifying these claims usually requires time-consuming wear trials. Enter MODY.

We measure support levels (low, medium or high) with our standardized method and MODY testing device.

MODY measures the support level and movement reduction:

We analyze support while the breast is moved in user-specific directions (up/down, right/left, forward/backward).

Using our 3D-printed torso with moldable breast, we test different cups and sizes.

Yes. The MODY testing device can be used for all types of bras.

Although the MODY device was developed with sports bras in mind, we can use it to measure the movement reduction in any bra type or other support garment.

Testing provides objective and reproducible results, without human influence.

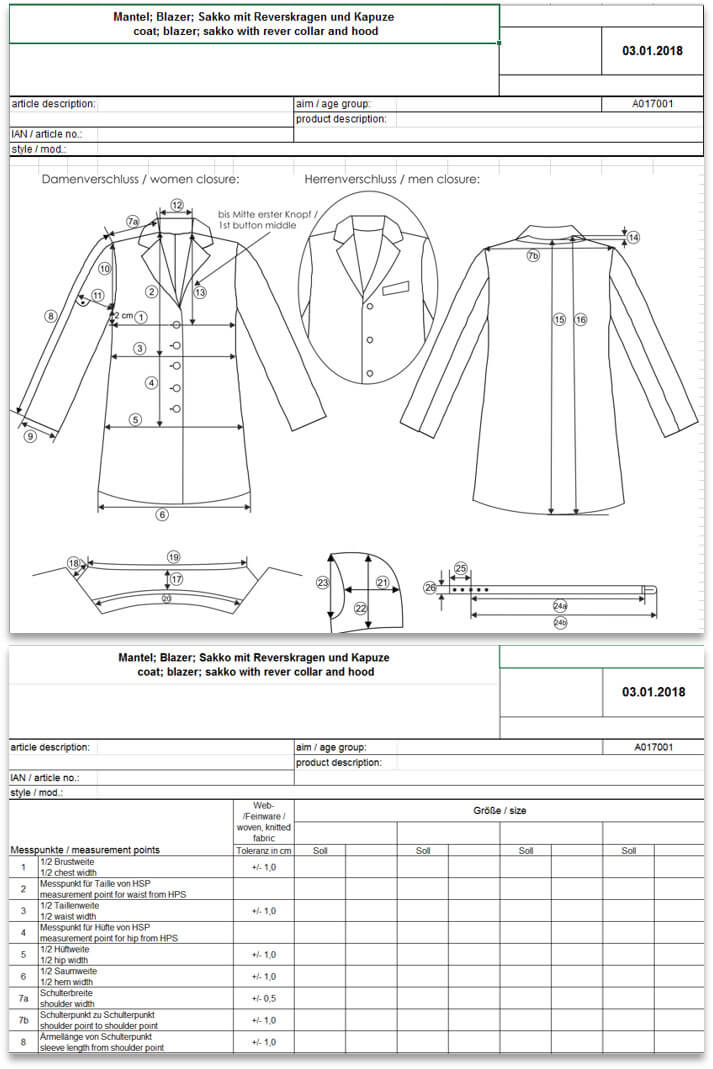

Hohenstein has decades of experience in fit and pattern development. We measure body data, optimize patterns and verify fit. We invest in technology, lead 3D design research and have a large pool of human testers.

Our MODY data is combined fit testing and pattern optimization to develop the desired support level - for the specific users and activities.

Our neutral assessment validates shaping claims by combining compression testing and fit/pattern development.

Shaping effects can be measured by comparing body measurements with merged scans, silhouette smoothing with cross section analysis and 3D body geometry with 3D analysis/quantification.

Acceptance and use of workwear, especially protective garments (PPE), depends on fit. In addition, workwear must allow the wearer to move without restriction. Fit in motion studies consider the user's relevant movements.

Technical performance descriptions ensure proper manufacturing, quality and use.